Proactive Maintenance Services

Oil Analysis

Our typical predictive maintenance (PM) programs integrate oil analysis with other techniques such as vibration analysis, infrared thermography, and ultrasonic testing

Dynamic Balancing

Excessive imbalance in rotating equipment has detrimental consequences, including diminished quality, reduced productivity, accelerated wear and tear, increased operator fatigue, and higher energy consumption. This issue impacts a wide range of rotating components, such as fans, couplings, spindles, and many more. Our dynamic balancing services excel at identifying the root causes of premature failures in rotating machinery across diverse sectors, including scientific, industrial, and technical industries. Contact us today to learn more about how our expertise can enhance the performance and reliability of your equipment.

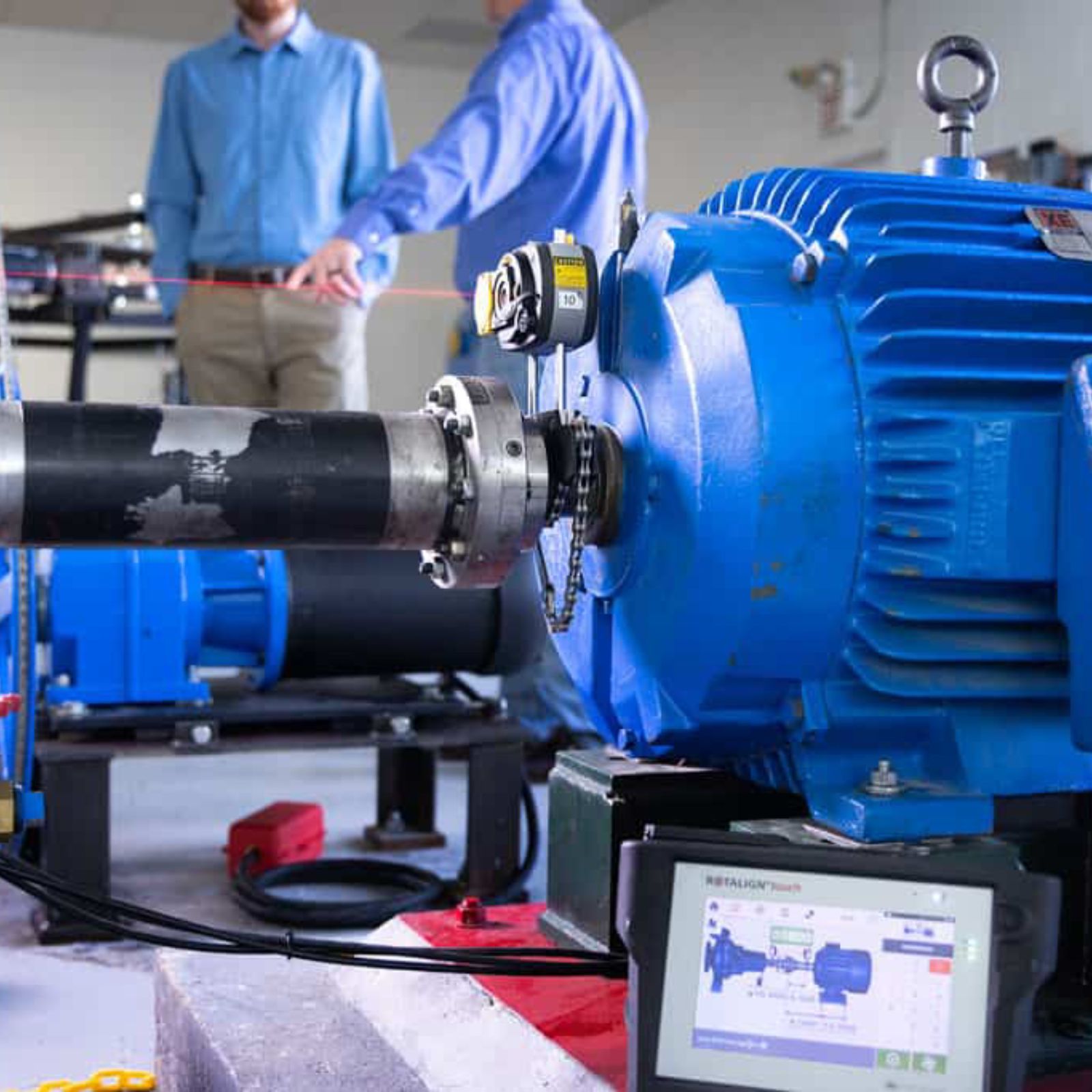

Laser Alignment

We offer precise laser alignment of your equipment using the most advanced technologies available, ensuring optimal performance and longevity.

Infrared Thermography

We provide precise infrared testing and inspection services to pinpoint and report potentially dangerous and costly issues before they escalate. Our expertise in infrared testing and thermographic imaging has earned us the trust of facility managers, industry specialists, and businesses of all sizes across the nation, spanning every industrial sector."Predictive Maintenance: Using condition monitoring to anticipate and prevent failures.